Training

Expand Your Knowledge with Training by Industry Experts.

Expand Your Knowledge With Training by Industry Experts

Swagelok® is a recognized global leader in training installers, supervisors, engineers, operators, and managers in the proper use and installation of fluid system components. The hands-on training sessions provide participants with an advanced understanding of processes that enhances workplace safety, improves efficiency and productivity, saves time, and reduces cost.

Browse Trainings

Our Swagelok® certified trainers provide high-impact, quality training either in a classroom or at your location. We offer various trainings on leak-tight installation of tube fittings, tube bending, and product selection.

Viewing Details:

.jpg?width=600&height=250&name=22-20077%20(1).jpg)

Tubing System Training Program – Hydrogen Applications

Who Can Benefit

Installers, technicians, engineers, designers, QC/QA inspectors, and others responsible for designing, installing, maintaining, and/or inspecting tubing systems in hydrogen and small molecule gas delivery systems.

Course Aims

The aim of the Swagelok Tubing System Training Program for hydrogen applications is to equip personnel with the knowledge and skills needed to build safe, dependable, and leak-tight fluid systems capable of handling the unique challenges posed by hydrogen, including its small-molecule nature, potential for leakage, and the need for high-pressure storage in various industrial applications.

Course Contents

- What is Hydrogen?

- Hydrogen Compatible Materials

- Risk Mitigation and Best Practices

- Tube Fitting Installation

- Tube Bending

- Tube Fitting Installation Inspection

- Higher Pressure Module

- FK Medium-Pressure Tube Fittings

- Cone and Thread Fittings

- Leak Testing

- Knowledge Test

Certification

Swagelok® Certificate of Completion - Valid for 3 years

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

.jpg?width=600&height=250&name=Photography-Field%20Engineer131(2).jpg)

Tubing System Training Program – Oil and Gas Applications

Who Can Benefit

Installers, engineers, designers, QC/QA inspectors, and others responsible for designing, installing, maintaining, and/or inspecting tubing systems in upstream oil and gas applications.

Course Aims

The aim of the Swagelok Tubing System Training Program for Oil and Gas applications is to address the JIP33 S-716 requirement and provide participants with in-depth instruction on industry best practices to ensure the high integrity of tubing systems.

Course Contents

- Safe installation practices when working with tubing systems

- Correct material selection and engineered combinations

- Correct storage, handling, and preparation of tubing

- Tube installation, routing, and support

- Swagelok® two ferrule tube fitting Installation

- Swagelok® FK series medium-pressure tube fittings and cone and thread Installation

- Tube bending

- Tube fitting installation inspection

- Straight and tapered thread Installation practices

- Safe operation of fluid systems and leak-free performance

Training Materials

All attendees will receive a Swagelok® Tube Fitter’s Installer’s Guide, Hand Tube Bender manual, and gap inspection gauge for 1/4-inch (6mm), 3/8-inch, and 1/2-inch (12 mm) tube fitting sizes.

Certification

Swagelok® Certificate of Completion – Valid for 3 years, subject to successful completion of both practical and theoretical exam.

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

.jpg?width=600&height=250&name=23-20080(2).jpg)

Tubing System Training Program – Chemical and Refining Applications

Who Can Benefit

Installers, engineers, designers, QC/QA inspectors, and others responsible for designing, installing, maintaining, and/or inspecting tubing systems in midstream and downstream chemical and refining applications.

Course Aims

The aim of the Swagelok Tubing System Training Program for Chemical and Refining applications is to address the small-bore tubing training needs for midstream and downstream applications. It covers tube fitting installation, inspection, tube bending, and other relevant topics.

Course Contents

- Tube Selection, Installation and Routing

- Tube Preparation

- Tube Fitting Installation

- Leakage & Safety Considerations

- Taper & Straight Thread Installation

- Plugs, Caps & Tube Adapters

- MHSU Operation & Maintenance

- Hand Tube Bender, Bending Methods & Offset Bends

- Bench Top Tube Bending

- Tube Fitting Installation Inspection

- Visual Inspection, Troubleshooting & Fault Identification

- Inspection Practical Exercise

Training Materials

All attendees will receive a Swagelok® Tube Fitter’s Installer’s Guide, Hand Tube Bender manual, and gap inspection gauge for 1/4-inch (6mm), 3/8-inch, and 1/2-inch (12 mm) tube fitting sizes.

Certification

Swagelok® Certificate of Completion – Valid for 3 years, subject to successful completion of both practical and theoretical exam.

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

Thread Identification Essentials

Who Can Benefit

Technicians, maintenance, and engineering personnel who requires knowledge and understanding on how to identify Common Thread Forms, Small Bore Tubing ("SBT") Connections and Configurations.

Course Aims

To provide delegates with the tools and understanding on how to correctly identify common thread forms and SBT components and identify the pressure capabilities of the connections and pressure injection injuries.

Course Contents

- Thread Identification - Practical and Theoretical Activities

- Tapered Threads: NPT, BSPT (ISO7/1)

- Straight (Parallel) Threads: BSPP (ISO228/1), SAE/MS, JIC (AN), Metric, etc.

- Tapered Threae Sealant Application

- Straight Thread Seal Mechanisms

- Common SBT System Connections and Configurations

- Pressure Ratings Awareness

- Pressure Injection Injuries Awareness

- Pressure Injection Injuries Awareness

Certification

Swagelok® Certificate of Completion - Valid for 3 years

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

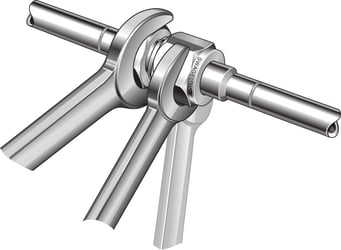

Swagelok VCR/VCO Fitting Installation Essentials

Who Can Benefit

Technicians, maintenance and engineering personnel involved in the installation, maintenance, inspection and design of small bore tubing and piping systems.

Course Aims

To provide delegates with an introduction to the functions and the sealing principles of face seal fittings. Correct procedures for assembly and reassembly are reinforced through the use of hands-on demonstrations and exercises. The course objectives are accomplished through the use of graphic illustrations, video training, product samples and hands-on experience.

Course Contents

- Tube preparation and variables

- The Swagelok Tube Fitting

- The key design elements of face seal fittings

- Considerations when installing the fitting in Ultra-High Purity Systems

- Review the importance of installation techniques which will extend the life of the fitting and ensure a leak-tight system

- Troubleshooting exercises designed to help delegates identify the most common installation errors

- OPTECH rig training and troubleshooting practical exercises

- Identification of VCR gasket types, options and usage

Certification

Swagelok® Certificate of Completion - Valid for 3 years

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

Hose Essentials

Who Can Benefit

Technicians, maintenance and engineering personnel who requires knowledge and understanding on hose and flexible tubing selection, installation, inspection and best practices.

Course Aims

To provide delegates with comprehensive knowledge on hose and flexible tubing construction, components, identification, selection, installation and best practices. The training covers inspection practices in line with the energy institute guidelines.

Course Contents

- Hose and flexible tubing construction

- The components of a hose assembly

- Hose assembly identification

- Hose selection considerations

- Hose inspection considerations

- Troubleshooting and examples of bad practices

- Hose installation and inspection; practical activities in line with the industry guidelines

Certification

Swagelok® Certificate of Completion - Valid for 3 years

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

Valve Essentials

Who Can Benefit

Technicians, maintenance and engineering personnel who require knowledge and understanding of how to choose the right valves for your applications.

Course Aims

To provide foundational system knowledge that helps to reduce costs, ensure safety and extend the production cycle in your valve systems by identifying proper valve types and functions, understand and identify constructions and common issues.

Course Contents

- Identifying valve types, functions, constructions and operation

- Understand proper installation, repair and troubleshooting of valves

- Define leakages and how to control the defined flow and understand the system's factors impacting the flow

- Identify and list factors affecting the service life

- Understand and learn to read the flow and system are factors impacting the flow

- Learn to read the flow curves and P/T tables.

Certification

Swagelok® Certificate of Completion

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

Tube Bending Essentials

Who Can Benefit

Technicians, maintenance and engineering personnel looking to gain valuable knowledge and experience in tube bending both theoretically and practically. The course covers hand tube bending from 1/8" to 1/2" OD (3mm to 12mm OD).

Course Aims

To provide delegates with a comprehensive understanding of the various tube bending methods utilizing the Swagelok® Hand Tube Bender. Each delegate will complete various exercises comprising of 45, 90 & 180-degree bends on different planes using offset calculations and measure, then bend the tubing to fit out an enclosure internally & externally with tubing runs.

Course Contents

-

Understanding tube bending terminology

-

Variables - springback, stretch and gain

-

Bend layout calculations: Measure bend, Pre-measure then bend

-

Overall length calculation to avoid wastage

-

The three marks used in tube bending

-

Offset bend calculations

-

Troubleshooting- tube bending defects

-

Swagelok® Hand Tube Bender - practical activities

-

Swagelok® Bench Top Tube Bender - practical activities

Certification

Swagelok® Certificate of Completion - Valid for 3 years

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

Tube Fitting Installation Inspection Essentials

Who Can Benefit

Technicians, maintenance and engineering personnel involved in the installation, maintenance, inspection and design of small bore tubing and piping systems.

Course Aims

To provide a comprehensive understanding on how to mitigate and minimize the risk of leakage through proper inspection.

Course Contents

- Identify correct tube system placement and correctly install Swagelok® Tube Fittings

- Identify mixed component fittings and the use of correct tubing type

- Point out common tube bending defects

- Identify leakage errors and the importance of proper assembly

- Identify compliant NPT thread installations

- Demonstrate the correct use of thread tape

Certification

Swagelok® Certificate of Completion - Valid for 3 years

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

Tube Fitting Installation Essentials

Who Can Benefit

Technicians, maintenance and engineering personnel involved in the installation, maintenance, inspection and design of small bore tubing and piping systems.

Course Aims

To provide foundational tube fitting knowledge that will minimize the risk of leakage and ensure the integrity of your system.

Course Contents

- Proper tubing selection, cutting and deburring

- Assemble Swagelok® tube fittings correctly

- Differences in tube fitting designs, components and the importance of proper assembly

- Identify thread types and installation practices

Certification

Swagelok® Certificate of Completion - Valid for 3 years

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

Swagelok® M200 Welding

Who Can Benefit

Welding Technicians or Engineers who would like to increase their knowledge on orbital welding, specifically using Swagelok® M200 welding equipment.

Course Aims

To provide delegates with a comprehensive understanding of the Swagelok® M200 power supply and related products. To instruct on set-up, operation and purging. Understand how to address maintenance and troubleshooting techniques to increase users' awareness, efficiency and improve production.

Course Contents

- Basic CTAW principles relating to Orbital Welding

- Understand the features of Swagelok® M200 system

- Identify and rectify electrode faults

- Understand purging and shielding gas techniques

- Correct system setup and fixturing

- Generate weld programs

- Carry out weld evaluation and adjustments

Certification

Swagelok® Certificate of Completion

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

Medium & High Pressure Cone & Thread Essentials

Who Can Benefit

Technicians, maintenance and engineering personnel involved in the installation, maintenance, inspection and design of medium and high pressure coned and threaded tubing systems

Course Aims

To provide delegates with a comprehensive understanding of medium and high-pressure fittings and related products. To educate our delegates on, correct coning and threading procedures, installation, maintenance and troubleshooting techniques. To increase system efficiency and improve system safety.

Course Contents

- Medium & high pressure tubing

- Coned & threaded connections

- Medium & high sealing features

- Assembly procedure & torque values

- Component Identification

- Needle, ball & check valves

- Safety consideration

- Tube preparation and handling

- Coning, threading and installation practical activities

Certification

Swagelok® Certificate of Completion

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

Tube Fitting Installation & Tube Bending Training

Who Can Benefit

Technicians, maintenance and engineering personnel involved in the installation, maintenance, inspection and design of small bore tubing and piping systems.

Course Aims

To provide delegates with a comprehensive understanding of Swagelok® Tube Fitting and related products. To instruct on installation, maintenance and troubleshooting techniques to increase system efficiency and improve system safety.

Course Contents

- Medium and high-pressure tubing

- Safe tube fitting installation procedures

- Understanding leakage and it's implications

- Correct material selection

- Identify component parts required to make a leak-free connection

- Correct thread identification and sealing methods

- Metric versus Fractional component part identification

- Tube preparation and handling

- Tube bending

Certification

Swagelok® Certificate of Completion, plus wallet card. Valid for 3 years (subject to successful completion of both practical and theoretical exam

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

Process Analyzer Sampling System (PASS) Training

Who Can Benefit

- System and design engineers, chemists, integrators, highly trained technicians, and anyone with an engineering background interested in understanding the fundamentals of designing, constructing, operating or maintaining sampling systems

- Newer team members seeking basic training or experienced professionals who want a refresher

Course Aims

Swagelok® Process Analyzer Sampling System (PASS)training courses will teach you how to design and optimize process analyzer sampling systems, providing the sound design principles needed to prevent costly sampling system errors. Attendees will learn how to improve process accuracy and optimize analyzer performance by:

- Recognizing and diagnosing sample transport problems

- Calculating pressure drop in a fast loop or return line

- Preventing or controlling phase separation

- Reading and creating sample system schematics

- Designing and building your own sample system

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

Sampling System Problem Saving and Maintenance (SSM) Training

Who Can Benefit

-

Anyone who diagnoses, troubleshoots and maintains sampling systems, including sample system and analyzer technicians, maintenance personnel and system engineer

- Newer team members seeking basic training or experienced professionals who want a refresher

Course Aims

Swagelok® Sampling System Problem Solving and Maintenance (SSM) training courses will teach you how to troubleshoot a variety of common sampling system issues from the process line through sample disposal. Attendees will learn how to improve sample system performance by:

Course Contents

- Medium and high-pressure tubing

- Safe tube fitting installation procedures

- Understanding leakage and its implications

- Correct material selection

- Identify component parts required to make a leak-free connection

- Correct thread identification and sealing methods

- Metric versus Fractional component part identification

- Tube preparation and handling

- Tube bending

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Viewing Details:

Material Science

Who Can Benefit

- Engineers, managers, supervisors, buyers or purchasing agents, technical associates, and anyone involved in the material selection process.

- Newer team members seeking basic training or experienced professionals who want a refresher.

Course Aims

Swagelok® Materials Science Training courses teach you how to choose the right corrosion-resistant materials to help you keep your fluid systems leak-tight and operating efficiently. Through this course, you will learn which specific alloys resist corrosion and how they do it, how various materials behave, and how the industry standards impact your material choice. Whether you are dealing with sour oil and gas fields or aggressive precursor chemicals for semiconductor manufacturing, a strong understanding of materials science is invaluable.

Instructor

Swagelok® Certified Trainers

How to Register?

Please email us at enquiry@swagelok.com.my and our dedicated team will follow up with full details.

Register or Request Information

Register or Request Information

Register or Request Information

Register or Request Information

Register or Request Information

Register or Request Information

Register or Request Information

Register or Request Information

Register or Request Information

Register or Request Information

Register or Request Information

Register or Request Information

Register or Request Information

Register or Request Information

Register or Request Information

Register or Request Information

Feedback from our customers

Need more information, support, or quotation?

Give us a call at 603.8084.1818 or email us.