Analytical Subsystems

Swagelok pre-engineered subsystems (PrESS) for analytical applications are designed and assembled by fluid system specialists to be compact, accurate, and convenient to use.

Locally Built Analytical Subsystems

Pre-engineered and fully assembled fluid sampling and control subsystems can bring efficiency and consistency to your operations. Use Swagelok pre-engineered subsystems (PrESS) to deploy fully documented fluid sampling and control systems without worrying about acquiring and assembling multiple parts.

For use in all types of plants and facilities where liquids and gases are processed, our proven subassemblies minimize system footprints, simplify system design, and promote representative samples and accurate analytical results.

Categories

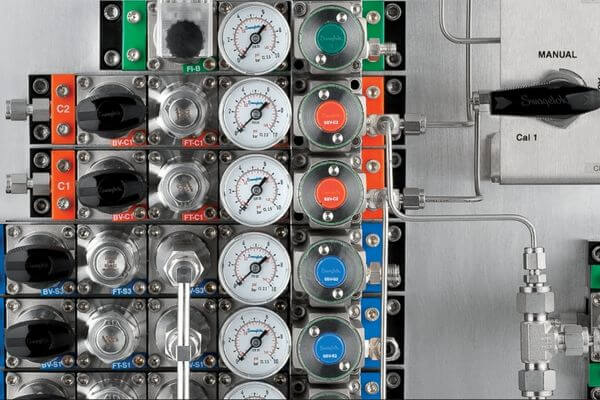

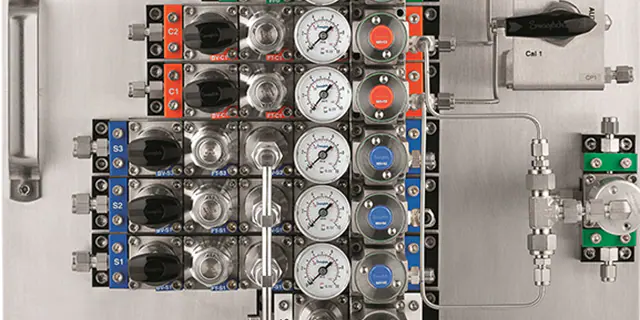

Calibration & Switching Modules (CSM)

Provides a discrete switch between process samples and conditions and selects process streams for analysis. Ensures inserted samples are at the correct pressure, temperature, flow, and filtration. Integrated flow loop design ensures consistent delivery times to the analyzer across all streams and eliminates any deadlegs or chance for cross-stream contamination.

The main function of the CSM is to condition and select process streams, or to select a calibration stream for analysis. At a minimum, each system must have two inlets—two process stream inlets, or one process stream inlet and a calibration stream inlet. The system selects a fluid for analysis in response to a pneumatic pressure signal from an external source, typically the analyzer. The signal opens one of the SSV double block-and-bleed valve modules corresponding to the stream containing the fluid to be analyzed.

Fast Loop Modules (FLM)

Handles high flows and long transport lines from tap to analyzer, reducing time delays for online analyser systems. Minimizes pressure drop for fastest response time. Mounts directly to process nozzles and is highly configurable. Located at the analyzer shelter and offering a bypass, the Swagelok FLM easily isolates the sample system while introducing a purge gas for system cleaning. It then extracts a sample through a filter while using the high flow rate to keep the filter element clean.

Designed to enable easy access to any component without disturbing other components in the system, the Swagelok FLM uses welded assemblies to reduce potential leak points and zero-clearance fittings in straight run tubing sections.

Field Station Modules (FSM)

The FSM transports a preconditioned, reduced-pressure process gas to an analyzer. Preconditioning a gas sample at the extraction point and transporting the sample at low pressure results in faster analyzer response time, less condensation, and less environmental impact. The FSM mounts directly to process nozzles and is highly configurable to match process conditions.

Reduces process gas pressure before transporting. Transporting a gas sample at low pressure means faster analyzer response time, less condensation, and a safer environment.

Fluid Distribution Headers (FDH)

Used as versatile manifolds in gas and liquid applications. Provides a flow path with multiple outlets, similar to a large branch fitting. Inlet on one end, drain on the other, and multiple outlets on either side, the FDH uses Swagelok®components for enhanced reliability. Swagelok FDHs can be used as distribution or collection manifolds, and are available in 1 and 2 in. sizes.

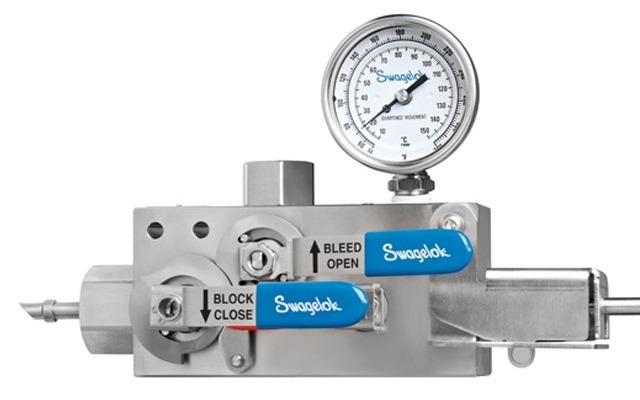

Sample Probe Modules (SPM)

Measures concentration of key components in gas and liquid streams to maintain precise process control. The SPM consists of a welded sample probe (SPW) or retractable sample probe (SPR) and a block-and bleed sample probe valve (SPV). The benefits of using sample probes in conjunction with sample probe valves includes improved safety, sample purity and timeliness.

1. Design

Starting with a phone conversation or meeting, we listen to understand your application, goals, and challenges. Topics might include pressures, temperatures, dimensional requirements, the presence of hazardous or flammable materials, and operator/maintenance access. We offer options and a quote. This is a collaborative process between our team and yours.

2. Fabrication

After design approval, our certified technicians will handle the fabrication. Swagelok assembly certification involves producing numerous complete assemblies, each of which is inspected by Swagelok manufacturing engineers and put through testing.

3. Quality Control

Every assembly is pressure tested with water to ensure proper assembly and high performance. In addition to standard testing, we can do helium leak testing, hydrostatic testing, nitrogen pressure testing, and pressure decay testing. The rigorous assembly process and 100% testing ensures you receive a high-quality reliable assembly.

4. Delivery

We clean and cap or bag the assembly to ensure contaminants are not introduced into your fluid system from the assembly. A test certificate is packaged with each assembly. Give us a call if you need installation advice.

What to Expect When Ordering Gas Distribution Systems

From a simple to complex design, we collaborate with you from start to finish. Here is how a project typically progresses:

Resources

Tips to Maintaining a Representative Sample in an Analytical Instrumentation System

Maintaining a representative sample within an analytical instrumentation system can be difficult. Learn how to identify major issues and avoid complications associated with a compromised representative sample from the experts at Swagelok. Read More.

Need more information, support, or quotation?

Give us a call at 603.8084.1818 or email us.