Gas Distribution Systems

Standardized, configurable gas delivery systems to help protect system operators.

Increased Uptime, Improved Process Accuracy, and Repeatability

Whether you need a standard solution or a custom arrangement, we can design and assemble a gas delivery system that is right for you. Our standard gas delivery panels come fully assembled and tested. They are easy to order from our application guide as single part numbers, minimizing the time your engineers spend on the specification and procurement of new systems. They are also highly configurable—we can add features or modify them to suit your requirements.

We design Swagelok gas distribution systems based on best practices. Our modular panels feature minimal threaded connections to reduce potential leak points, and they are intuitively labeled to promote safe, simple use, and maintenance. All our gas distribution systems are backed by the Swagelok Limited Lifetime Warranty.

Efficient Gas Distribution with Swagelok

Backed by 70-plus years of fluid system expertise and a global network of pressure control advisors, Swagelok is uniquely positioned to provide gas distribution systems and pressure control advisory services that help you ensure your facilities and sites are operating safely and efficiently. Learn how we can help you.

Choose From Modular Gas Distribution Subsystems

Swagelok gas distribution systems are built around one or a series of pressure regulation steps, and may include four subsystems:

Swagelok® Source Inlet (SSI)

The source inlet establishes a connection between the high-pressure gas source and the distribution system. It is important the inlet is built with appropriate cylinder connections, hoses, tubing, filters, and vent, purge, and relief functions to ensure that gas can be safely fed into the primary gas pressure control or automatic changeover.

For a single gas cylinder, the assembly can be as simple as a hose and connector, while multiple cylinders may require a manifold incorporating many hoses and valves.

We offer:

- Highly configurable options to purge or vent gases when changing bottles, always ensuring operator safety

- Available option to vent individual lines to maximize uptime

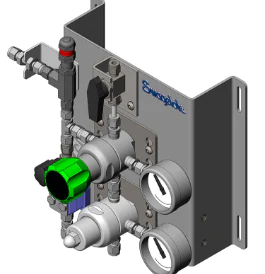

Swagelok® Gas Panel (SGP)

As the primary gas pressure control, the SGP completes the first pressure reduction of the source gas and ensures it is delivered at the correct flow rate to the next stage of the system. Pressure reduction is accomplished in either one stage with a single pressure regulator or two stages through a dual pressure regulator arrangement.

We offer:

- Modular panels that are easy to service as any part can be detached via a Swagelok connection, so the panel never needs to be removed

- Options implemented around the regulator and valves for color-coding if required for your site

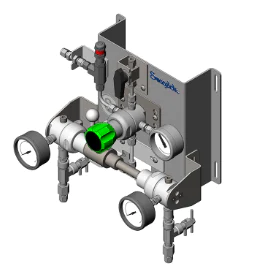

Swagelok® Changeover (SCO)

The automatic changeover system seamlessly switches from one gas source to another to ensure an uninterrupted supply. This is accomplished through staggered set points of two pressure regulators, allowing the system to continue to operate as the primary gas source is changed. Our changeover station allows for customer-specified changeover set points to help reduce wasted gas left in cylinders.

We offer:

- More assurance that the changeover point remains constant

- Optional line regulation if your system incorporates a point-of-use regulator downstream—this can eliminate the additional cost of a regulator on the SCO

- Flexibility to set changeover pressure to your specification

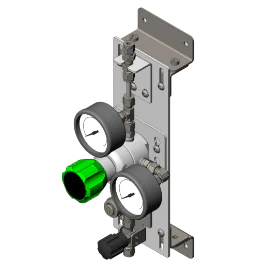

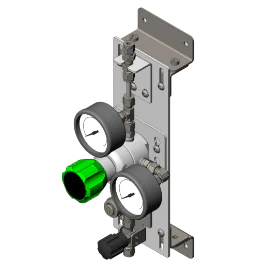

Swagelok® Point-Of-Use (SPU)

The point-of-use provides the critical last stage of pressure control prior to the gas being used. These are often the least complex of the four main subsystems, typically having a pressure regulator, gauge, and isolation valve. Point-of-use systems offer a convenient and accurate method of adjusting pressure to meet test bench or equipment needs.

We offer:

- Standardization and consistent operation at the point-of-use

- Top-to-bottom or bottom-to-top flow to meet your setup needs

- Flat plate, bottom mount, top mount, and wall mount options

- Compact design

What to Expect When Ordering Gas Distribution Systems

Here are the main steps to design and build a custom gas distribution system:

1. Design

Starting with a meeting or phone conversation, we gather information needed to specify the module or system properly. Topics include pressure, temperature, phase, presence of hazardous or flammable material, appropriate materials of construction (including coatings, etc.), surface treatments, and purge requirements.

2. Fabrication

After design approval, certified technicians handle fabrication. Swagelok assembly certification involves producing dozens of samples, each of which is inspected by Swagelok manufacturing engineers and put through destructive testing. Passing requires a 100% score.

3. Quality Control

Every assembly is pressure tested with water to ensure proper assembly and high performance. In addition to standard testing, we can do helium leak testing, hydrostatic testing, nitrogen pressure testing, and pressure decay testing. The rigorous assembly process and 100% testing ensure you receive a high-quality, reliable assembly.

4. Delivery

We clean and cap or bag the assembly to ensure contaminants are not introduced into your fluid system from the assembly. A test certificate is packaged with each assembly. Assemblies can be installed immediately. Give us a call if you need advice on installation.

Resources

How to Reduce Your Maintenance Spend by Improving Gas Distribution

Learn how easy-to-use gas panels and an overall more efficient gas distribution and delivery system can help laboratories, refineries, and other facilities drive down maintenance costs. Read More.

Need more information, support, or quotation?

Give us a call at 603.8084.1818 or email us.