Mechanical Seal Support Systems

We help you keep your rotating equipment online and operating efficiently with Swagelok mechanical seal support kits and assemblies.

Minimized Downtime, Reduced Costs, and Enhanced Operational Efficiency

We offer mechanical seal support system as kits and assemblies that are easy to install and are backed by The Swagelok Limited Lifetime Warranty. Our seal support systems are available in various American Petroleum Institute (API) plan configurations and are assembled according to industry best practices as detailed in the fourth edition of the API 682: Pumps—Shaft Sealing Systems for Centrifugal and Rotary Pumps standard.

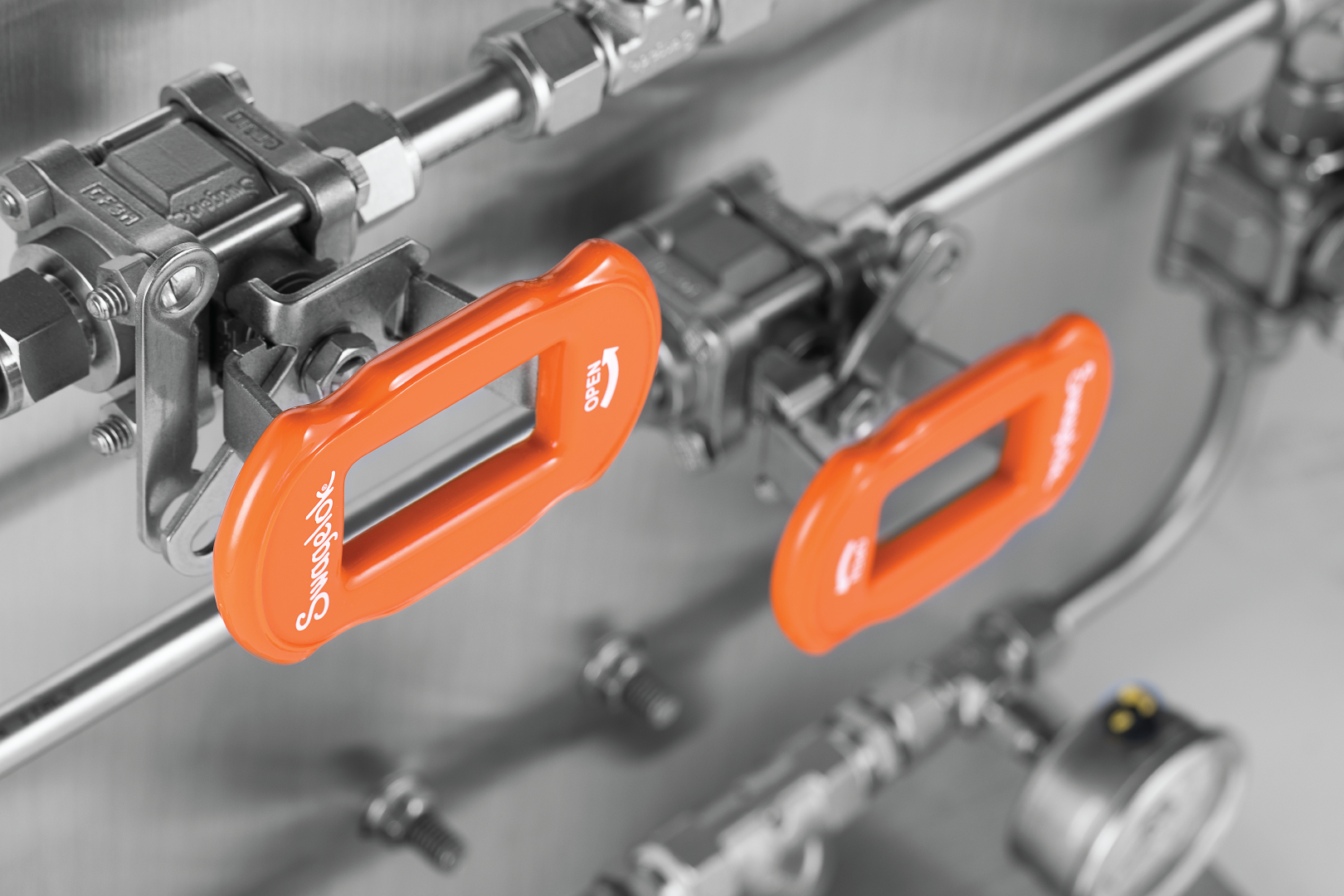

Swagelok mechanical seal support kits and assemblies feature standard designs that include the minimum arrangement of components as specified by API 682. We avoid pipe threads and limit the number of connections wherever possible when building seal support systems, minimizing potential for costly leaks.

Swagelok Seal Plan Kits and Assemblies

Swagelok Seal Support Systems supply either a gas or a liquid to a mechanical seal to regulate the environment in which the seal operates, protecting rotating equipment from damage. These systems provide lubrication to seal faces, control pressure and temperature in the seal chamber and seal, flush the seal of contamination and/or residue build up, and prevent system process fluid from leaking to atmosphere.

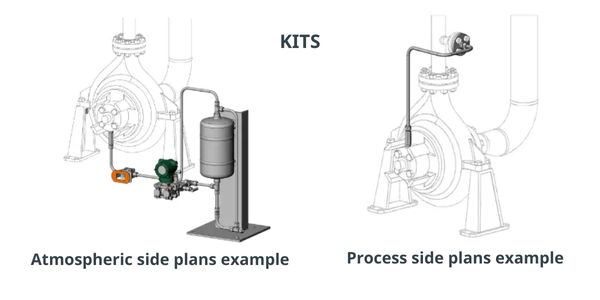

Seal Plan Kits

Seal plan kits are a collection of components used to connect the seal support plan to the pump. Each kit contains everything needed for proper installation, including an engineered drawing, making it simple to standardize how plans are connected to the pump during turnarounds or other projects. Kits also adhere to API best practices by showing technicians where to bend tubing to eliminate potential leak points through the reduction of elbow fittings and pipe threads.

Kits include all components needed to complete the plan:

- atmospheric side plans 51, 62, 65A, and 65B; and

- process side plans 11, 12, 13, 14, 21, 22, 23, 31, 41.

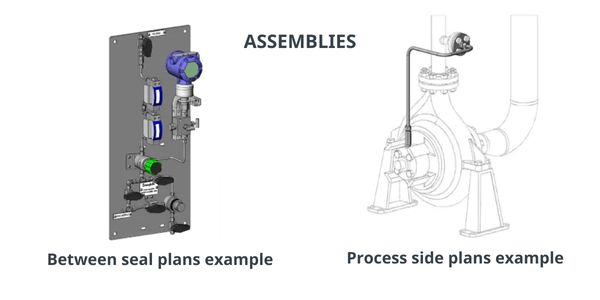

Seal Plan Assemblies

Seal plan assemblies are panels, seal pots, or skid systems that comprise the majority of the API seal support plans. The seal plan assembly ordering numbering structure allows users to select a variety of configurations and additional system components to meet specific site or application requirements. Options and configurations not listed in the ordering numbering structure are also available. Seal plan assemblies can be ordered alone or with the associated field installation kit to provide a standard installation for site personnel.

Explore Swagelok between seal plans and process side plans available as seal plan assemblies:

- Between seal plans 52, 53A, 53B, 53C, 54, 55, 72, 74, 75, 76, and 72/76; and

- Process side plan 32

What to Expect When Ordering Mechanical Seal Support Systems

Here are the main steps in producing a custom solution for mechanical seal support:

1. Design

Starting with a phone or face-to-face conversation with our team, we gather information about your application, seal chamber conditions (flow, temperature, pressure, etc), location of mechanical seals, maintenance routines, tubing runs, and other data.

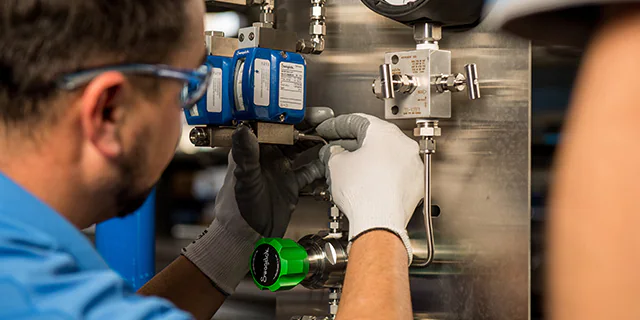

2. Fabrication

Our Swagelok-certified technicians handle the fabrication; Swagelok assembly certification involves producing dozens of samples, each of which is inspected by Swagelok manufacturing engineers and put through testing.

3. Quality Control

4. Delivery

Resources

Building Better Mechanical Seal Support Systems

Learn how API 682 guides the design and assembly of mechanical seal support systems and how applying a few best practices can help your systems last longer and work better. Read More.

How Fluid System Fabrication Can Alleviate Resource Constraints

There are several common fluid systems that successful plant operations depend on, and choosing the right fabrication provider can be highly beneficial if you’re short on resources. Read More.

Need more information, support, or quotation?

Give us a call at 603.8084.1818 or email us.